Fall Through Temporary Roof Opening

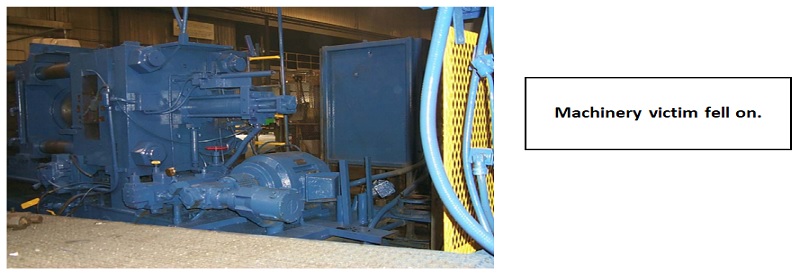

A 50-year-old male cleaner died when he fell approximately 35 feet through a temporary roof opening and was impaled on a piece of equipment on the factory floor below. He had been cleaning an exhaust fan with a pressure washer on the factory roof. He and two co-workers had removed the fan from its casing creating a temporary roof opening and set the fan beside the roof opening for cleaning.

Facing the fan with his back to the opening, the cleaner apparently stepped backwards and fell through the opening.

He fell onto a 1200-ton die-casting machine on the factory floor. Onsite personnel working nearby heard the cleaner fall onto the machine. They summoned help and factory-employed emergency response personnel responded to the scene, assessed the situation and called for an ambulance. Local emergency medical personnel and police arrived at the scene and contacted the coroner. The coroner arrived and declared the victim dead at the scene.

Lessons to Learn and Live By

This type of incident is completely avoidable if safety precautions are in place.

1. Openings in roofs, floors, and walls must be barricaded, protected with a guardrail system, or covered with marked covers to prevent someone from unintentionally falling through them.

a. The employer stated that the factory initially did not want the holes covered up when the fans were removed because it would keep air from flowing out of the factory.

b. After this incident occurred, the company constructed covers of 2 x 4s and plywood nailed together to be placed over the temporary holes in the roof while the fans were removed.

c. Additionally, a moveable four-wall, five-foot-high barricade could have been constructed for the roof openings. This would have allowed the factory air to exhaust through the roof openings while the fans were being cleaned.

2. Fall protection equipment must be worn when workers are performing work at heights. Properly used and anchored fall protection would likely have saved this man’s life.

a. Besides barricades around the roof openings, the laborers could have worn appropriate harness devices tethered to roof anchors.

b. The roof of the building was flat and there are at least two types of roof anchors designed for use on flat roofs.

3. Train employees on and enforce the use of, safe work practices related to walking and working surfaces.

a. Training should include how to properly erect, maintain, disassemble, and inspect fall equipment and systems such as guardrail systems, personal fall arrest systems, warning line systems, safety monitoring systems, controlled access zones and other protection systems/devices to be used.

b. Train workers and supervisors on hazard identification, the process for reporting hazards, and what each group can do to avoid or fix hazards.

4. Create an environment where it is expected and accepted that workers speak up about dangerous work or unsafe conditions.

5. Hold supervisors accountable for following and enforcing safety procedures in every situation. There are no do-overs when it comes to death. Shortcuts and excuses are not an option.

https://uknowledge.uky.edu/cgi/viewcontent.cgi?article=1007&context=face_falls_reports