ASME Pipe Marking Standard – Quick Tips

Hazardous materials flow through miles of piping in a wide variety of facilities. Just like hazardous materials in other containers, piping systems should be appropriately labeled. The American Society of Mechanical Engineers (ASME) A13.1 Scheme for the Identification of Piping Systems standard addresses pipe marking by offering a common labeling method for use in all industrial, commercial and institutional facilities as well as in buildings used for public assembly. This standard does not apply to buried pipelines or electrical conduit.

Label Requirements

Pipe marking labels must effectively communicate the contents of the pipes and give additional detail if special hazards (such as extreme temperatures or pressures) exist. The legend should be short in length and easy to understand. For example, the legend “Steam 100 PSIG” specifies the contents as well as the additional pressure hazard. An arrow should be used in conjunction with the legend to show which direction the material flows. If flow can be in both directions, arrows in both directions should be displayed.

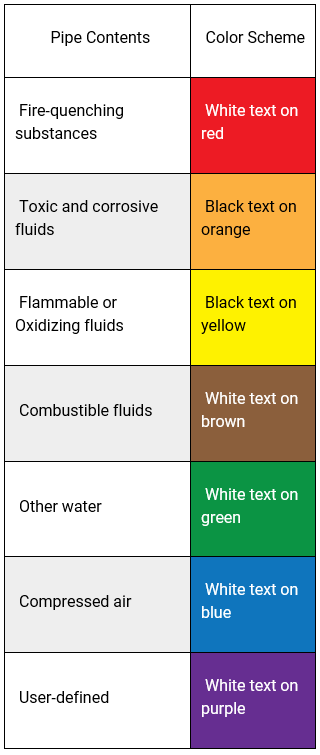

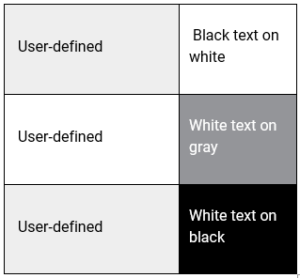

ASME A13.1 was last updated in 2015. It uses a color code chart with six standard color combinations and four user-defined combinations as shown below. The colors are based on the contents of the pipe and in general, the most hazardous feature of the contents is used to determine the colors used.

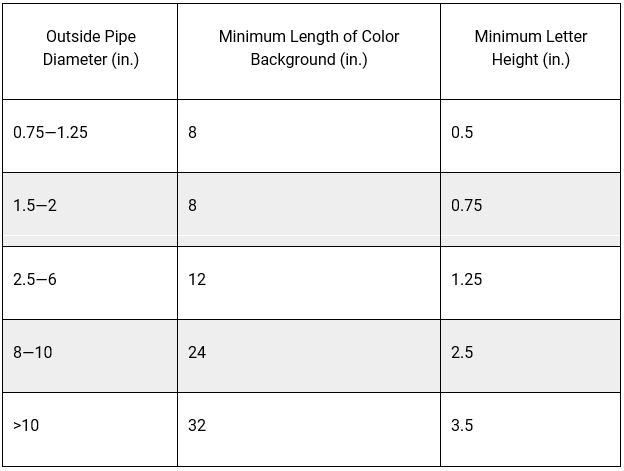

Pipe diameter determines the appropriate label and text sizes as shown below.

Label Placement

Labels should be positioned on the pipes so they can be easily seen and read from the normal angle of approach. For example, labels should be placed below the centerline of the pipe if the pipe is overhead and above the centerline if the pipe is below eye level. Labels should be located adjacent to valves and fittings, adjacent to changes of direction, on both sides of wall or floor penetrations, and at regular intervals on straight segment runs with spacing between that allows for easy identification (50 feet is the suggested maximum spacing, but closer spacing may be needed for visibility).

Summary

Unmarked pipes are a danger to both people and property. Accidents, injuries and damage to equipment can be caused by not knowing what is flowing through the pipes that surround us. By marking and identifying pipes, errors and accidents can be prevented. It also makes maintenance work easier and helps prevent time-consuming searches.

Commonly Asked Questions

Q: What if I have a pipe smaller than 0.75 inches in diameter?

A: For pipes of less than 0.75 inches in diameter, the use of a permanently legible tag is suggested. On many piping systems, there may be valves, actuators and transmitters that can be tricky to label with standard pipe markers. Valve tags can make labeling these awkward places quick and easy.

Q: Are particular shades of yellow, green, red and blue required for pipe labels?

A: Yes, ASME A13.1- 2015 references the technical definitions, color standards and color tolerances set forth in the American National Standards Institute (ANSI)/National Electrical Manufacturers Association (NEMA) Z535.1 Safety Colors standard which was last updated in 2017. The color shades suggested are intended to give the highest level of recognition to employees with both normal and color-deficient vision.

Q: Has ASME A13.1 been adopted by the Occupational Safety and Health Administration (OSHA)?

A: ASME A13.1 has not been incorporated by reference in 29 CFR 1910.144 (Safety Color Code for Marking Physical Hazards) or 1910.145 (Specifications for Accident Prevention Signs and Tags). It has been incorporated in a few of the specific special industry standards in 29 CFR 1910 Subpart R -pulp, paper and paperboard mills (29 CFR 1910.261) and textiles (1910.262) for example. Also, it is important to remember that industry voluntary consensus standards may be evidence that a hazard is recognized and there is a feasible means of correcting such a hazard. If a voluntary consensus standard is not followed, it is possible to be cited under OSHA’s General Duty Clause.

Sources

ASME A13.1-2015 Scheme for the Identification of Piping Systems

ANSI/NEMA Z535.1-2017 Safety Colors

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how