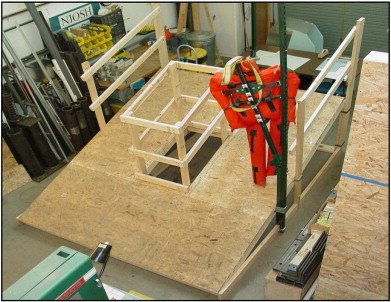

Is This a Safe Way to Guard a Floor Opening?

What is wrong with this picture?

The railing arrangement in this photo is in some ways more dangerous than the floor hole it’s guarding:

- There’s no intermediate railing; and

- The post ends jutting out from over the top railing are uncapped and could cause serious damage if workers stumble into them.

Moral: Make sure your floor hole guarding arrangements meet OSHA standards and don’t expose workers to additional hazards.

FLOOR HOLES & FALLS: 3 Reasons to Pay Attention

- Falls are the leading cause of workplace accidents

- 15% of all workplace deaths are the from falls (the second leading cause of fatalities trailing only motor vehicle crashes

- Many of these fall accidents and deaths are the result of stepping into floor holes like the one in the picture

MAKE SURE FLOOR HOLES ARE PROPERLY GUARDED

OSHA (Sec. 1910.23(a)(8)) says that floor openings must be guarded by EITHER:

1. A Floor Hole Cover of standard strength and construction;

OR

2. A Standard Railing and Toeboard on all exposed sides.

MAKE SURE RAILINGS ARE SAFE

According to OSHA (Sec. 1910.23(e)(1)), there are 5 things a railing must have to be considered “standard railing”:

- A top rail that’s smooth-surfaced throughout the length of the railing;

- An intermediate rail that’s located about halfway between the top rail and floor/platform/runway/ramp;

- Posts;

- At least 42 inches in height measured from the upper surface of the top rail to the floor/platform/runway/ramp;

- Ends of rails that don’t overhang the terminal posts (unless the overhang doesn’t constitute a projection hazard).

The railing in this photo is clearly not up to “standard.”