Outdoor Chemical Storage Buildings – Quick Tips

Safely storing hazardous materials and wastes is a necessity for many companies. Outdoor Chemical Storage Buildings provide an effective solution to fulfill this need. The National Fire Protection Association (NFPA) defines an outdoor chemical storage building as “a prefabricated structure, manufactured primarily at a site other than the final location of the structure, and transported completely assembled or in a ready-to-assemble package to the final location.” These buildings provide an economical means of storage and secondary containment because they eliminate the expense of constructing permanent structures. They also offer the additional benefit of being portable, allowing the buildings to be relocated should the need arise.

When selecting outdoor chemical storage buildings your choice will depend on the materials to be stored, how the building will be used, the volume of the materials being stored and the location of the building and design requirements.

Type of Material to Be Stored

If the materials to be stored are either flammable or combustible, you will need a building that meets the NFPA Code 30, Uniform Fire Code (UFC) Articles 79 and 80, or an equivalent local code. Check with the authority having jurisdiction (AHJ) to determine which code is locally enforced.

The class of the flammable-combustible material (refer to NFPA Code 30) can also dictate what type of building construction is required. Class I, II, or III flammable and combustible liquids will require either a non-combustible building or a fire-rated building. Non-combustible buildings are constructed of non-combustible material (such as steel), whereas a fire-rated building is constructed of non-combustible materials and includes fire resistant insulation in the walls. Fire-rated buildings are further divided into categories based on the fire resistance of the walls, roof and openings (doors and vents).

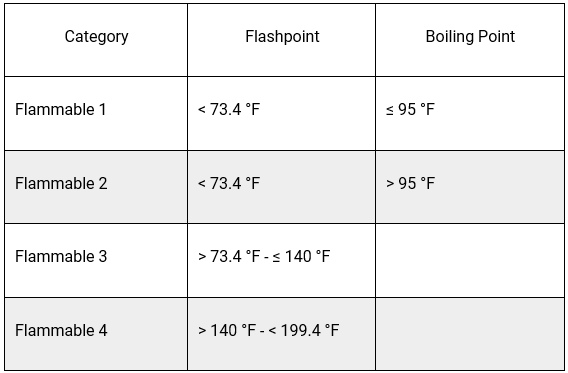

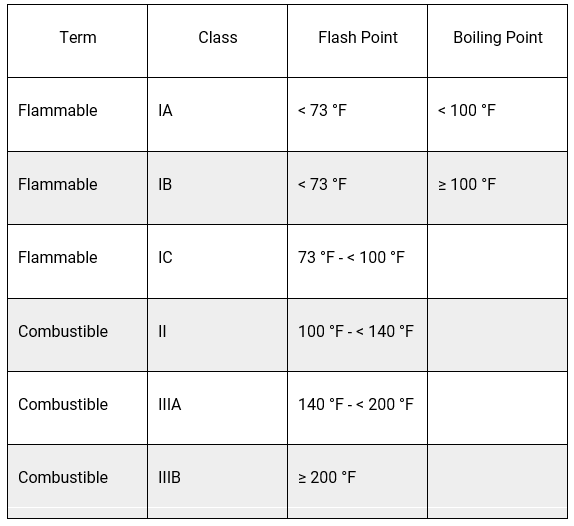

With the 2012 revision to the Occupational Safety and Health Administration’s (OSHA’s) Hazard Communication standard and the adoption of portions of the Globally Harmonized System of Classification and Labeling of Chemicals, flammable liquids are now either Category 1, 2, 3, or 4 flammable liquids. The NFPA fire codes still identify liquids as flammable IA, IB, IC or combustible II, IIIA and IIIB liquids. Information regarding the flammability of the chemical you are storing is located in Section 9 of the Safety Data Sheet (SDS).

OSHA’s Flammable Liquid Categories (29 Code of Federal Regulations 1910.106)

NFPA Flammable and Combustible Liquid Classifications

When storing non-flammable liquids, a non-combustible building may be sufficient, but you should check with the AHJ for specific requirements.

Storage vs. Dispensing

The design of the building will also be affected by whether or not you will be dispensing from containers stored in the building. Explosion relief panels are required for buildings that store and dispense Class IA liquids and that dispense Class IB liquids. Otherwise, an explosion relief panel is not required.

Amount of Material to Be Stored

The interior of the building should accommodate the number of containers required in a single layer and have adequate sump capacity to comply with the Environmental Protection Agency (EPA) Secondary Containment Requirements (40 CFR 264). To meet this regulation, the sump containment should be large enough to hold 100% of the volume of the largest container stored in the building or 10% of the total volume of all containers stored in the building, whichever is larger.

Location

The type of building you select will also have a bearing on the chosen location. Factory Mutual (FM), an insurance and testing agency, no longer specifies minimum distances between the storage building and any other main (occupied) building on the site and the property line of the facility. FM leaves the setback distances up to the AHJ.

Compliance and Approvals

Construction of outdoor chemical storage buildings must comply with a number of regulations including EPA 40 CFR 264, OSHA 29 CFR 1910.106, NFPA Codes 30 and 70, and UFC Article 79 and 80. In addition to the construction requirements, certain approvals may also be required for these buildings. These approvals include UL (Underwriters Laboratories) Classification and FM Approval. Additionally, certain states require that a Professional Engineer apply a Seal of Approval to the building, indicating that it meets all state regulations. Contact the AHJ for more details on the State Seal Program and to verify if your state requires an approval seal.

Options

A variety of options are available for outdoor chemical storage buildings. The options allow you to meet both your regulatory requirements and your custom design needs. Available options include electrical service, heating and cooling systems, fire suppression systems, exterior and interior lighting, shelving, ramps, insulation, emergency eyewash and shower and explosion-resistant features. .

More Assistance

If you have further questions regarding outdoor chemical storage buildings or if you would like help selecting and designing a building to meet your needs, contact your local Grainger Account Manager.

Commonly Asked Questions

Q: Can outdoor chemical storage buildings be moved from one location to another?

A: Yes. Outdoor chemical storage buildings are designed to be portable. When moving a building to a new location, be sure to confirm that the new location meets all required local codes. A building can also be moved indoors if needed. Buildings for flammable liquid storage being relocated indoors should have a continuous ventilation system that is exhausted to the outdoors, a four-hour fire rating, a fire suppression system and explosion relief panels directed towards a safe exterior location. Also, in most cases when storage is indoors and a sprinkler system is installed, the containment sump is required to be large enough to hold 100% of the volume of the largest container stored or 10% of the combined total volume of all of the stored containers, whichever is larger, plus the additional volume of the water discharged by the sprinkler system in 20 minutes. Again, be sure to consult your local Authority Having Jurisdiction (AHJ) to insure compliance with all local and/or state codes.

Q: Is there a difference between a chemical storage building and a chemical storage locker?

A: Yes. A chemical storage locker is usually smaller in size and generally doesn’t allow workers to enter the structure. Approval of storage lockers is limited to outdoor use only.

Q: Is there a difference between a chemical storage building and a chemical storage locker?

A: Yes. A chemical storage locker is usually smaller in size and generally doesn’t allow workers to enter the structure. Approval of storage lockers is limited to outdoor use only.

Q: Do chemical storage buildings need to be grounded?

A: Yes. According to the FM Approvals LLC, Approval Standard for Storage Buildings and Lockers Class Number 6049 General Design Requirements December 2013, a suitable means of grounding the building and individual containers must be provided. Grounding should meet the NFPA 70 requirements.

Sources

29 CFR 1910.106 Flammable Liquids

40 CFR 264 Standards for Owners and Operators of Hazardous Waste Treatment, Storage and Disposal Facilities

National Fire Protection Association Code 30 Flammables and Combustible Liquid Codes 2015 Edition

www.nfpa.org

Factory Mutual

Norwood, MA

www.fmglobal.com

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how