PPE Eye and Face – Quick Tips

Introduction

The National Institute for Occupational Safety and Health (NIOSH) reports that every day about 2,000 U.S. workers sustain job-related eye injuries that require medical treatment. However, safety experts and eye doctors believe the right eye protection can lessen the severity or even prevent 90 percent of these eye injuries.

Personal Protective Equipment (PPE) Requirements

General personal protective equipment (PPE) requirements are addressed in 29 Code of Federal Regulations (CFR) 1910.132 :

“Protective equipment including personal protective equipment for eyes, face, head and extremities, protective clothing, respiratory devices, and protective shields and barriers shall be provided, used and maintained in a sanitary and reliable condition wherever it is necessary by reason of hazards of processes or environment, chemical hazards, radiological hazards or mechanical irritants encountered in a manner capable of causing injury or impairment in the function of any part of the body through absorption, inhalation or physical contact.” (29 CFR 1910.132(a))

Eye and face protection requirements are outlined in 29 CFR 1910.133. Employers must ensure that each affected employee:

- Uses appropriate eye or face protection when exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors or potentially injurious light radiation

- Uses eye protection that provides side protection when there is a hazard from flying objects

- Who wears prescription lenses while engaged in operations that involve eye hazards wears eye protection that incorporates the prescription in its design, or wears eye protection that can be worn over the prescription lenses without disturbing the proper position of the prescription lenses or the protective lens

- Uses equipment with filter lenses that have a shade number appropriate for the work being performed for protection from injurious light radiation

Criteria for Protective Eye and Face Devices

More than 10 years ago (September 2009) OSHA issued a Final Rule that incorporated the latest versions of national consensus and industry standards for eye and face protective devices, head protection and foot protection. Additionally, OSHA also announced its use of “direct final rule” to ensure that when standards change, the law is automatically updated.

ANSI Z87.1

The first “standard” for head and eye protection dates to 1922 with the first edition of the Z2 standard by the War and Navy Department and the National Bureau of Standards.

In 1968, the eye and face protection standard was published with the Z87 designation, Z87.1-1968. Since then Z87.1 has been revised six times–1979, 1989, 2003, 2010, 2015 and 2020. Through these revisions, the purpose of this Standard has remained the same – to provide minimum requirements for eye and face protective devices including selection, use and maintenance of the devices.

ANSI/ISEA Z87.1-2020

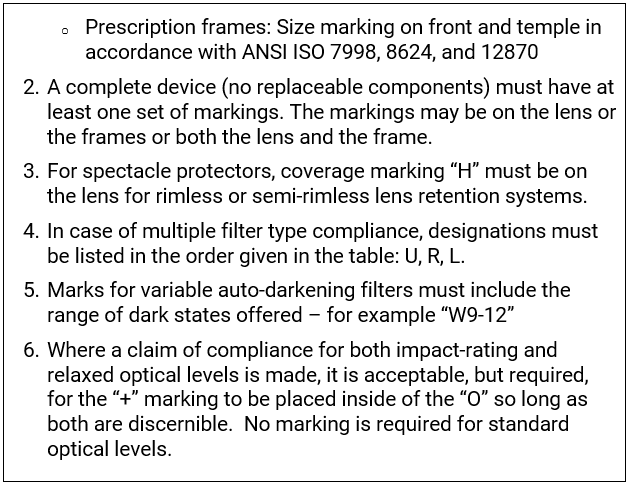

The 2020 revision continues to focus on product performance and harmonization with global standards. This allows new, innovative and compliant designs to enter the market. ANSI/ISEA Z87.1-2020 now includes criteria and required markings for protectors that offer relaxed optics for job tasks that may not require the historically stringent optical criteria. Hazard assessments are a must to determine if relaxed optics would be sufficient. It also now includes testing, performance and marking criteria for lenses with anti-fog properties and expanded welding filter shades.

ANSI /ISEA Z87.1-2020 sets forth numerous criteria related to the general requirements, testing, permanent markings, selection, care and use of “protectors.” A “protector” is a complete device (a product with all its components in the final use configuration) that meets the required performance criteria. Generally, the required tests must be performed on a specified number of complete devices. This number varies by testing protocol. For example, for high-mass impact four complete devices must be tested and for lateral protection one complete device must be tested. The newly added anti-fog lens treatment criteria is a lens-only assessment which is a departure from the final configuration approach. This lens-only approach is consistent with criteria in other global standards.

All original equipment manufacturers and non-original equipment manufacturers aftermarket components not sold with the original device must be tested and assembled with the original complete device in the as-worn condition. For aftermarket side shields, the side shields must be tested on representative frames for which the product is specified to fit. Documentation listing all devices that the component or accessory has been tested and is approved for must be made available by the manufacturer. The entity claiming compliance of the component is responsible for testing the assembled device.

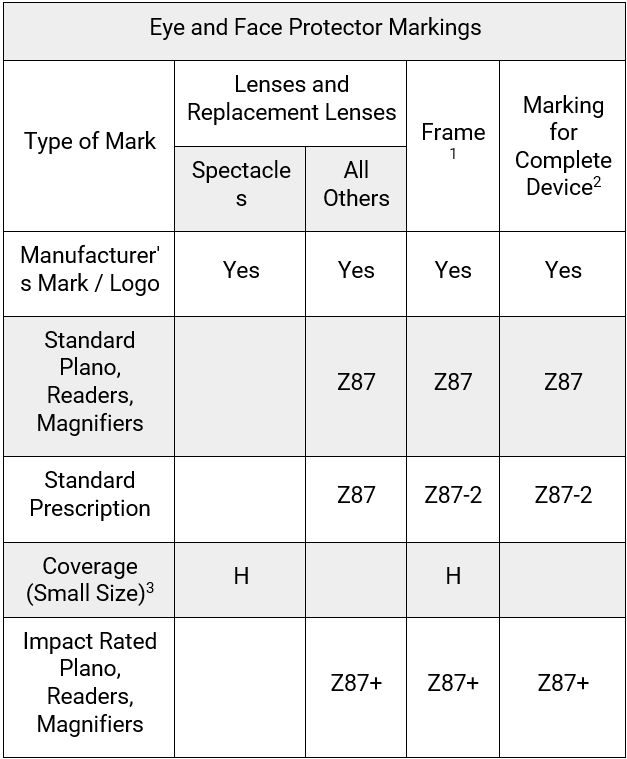

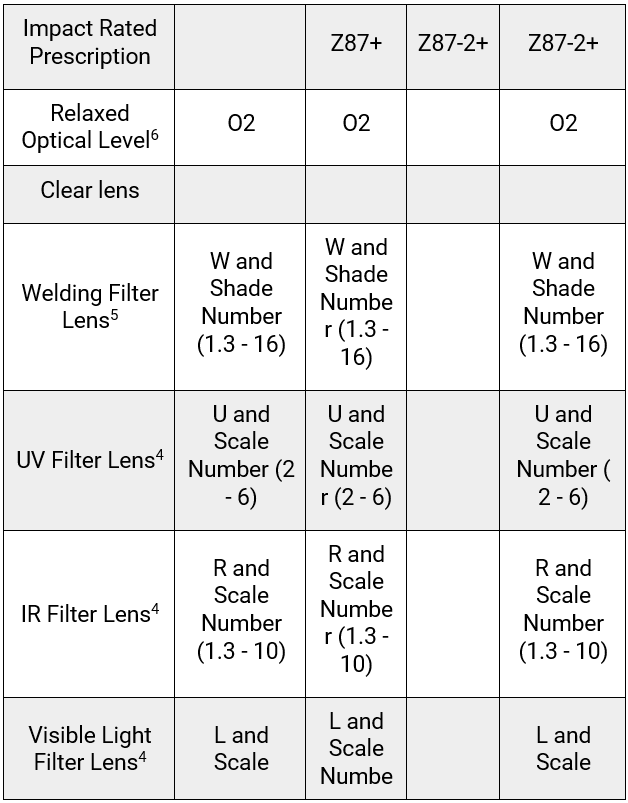

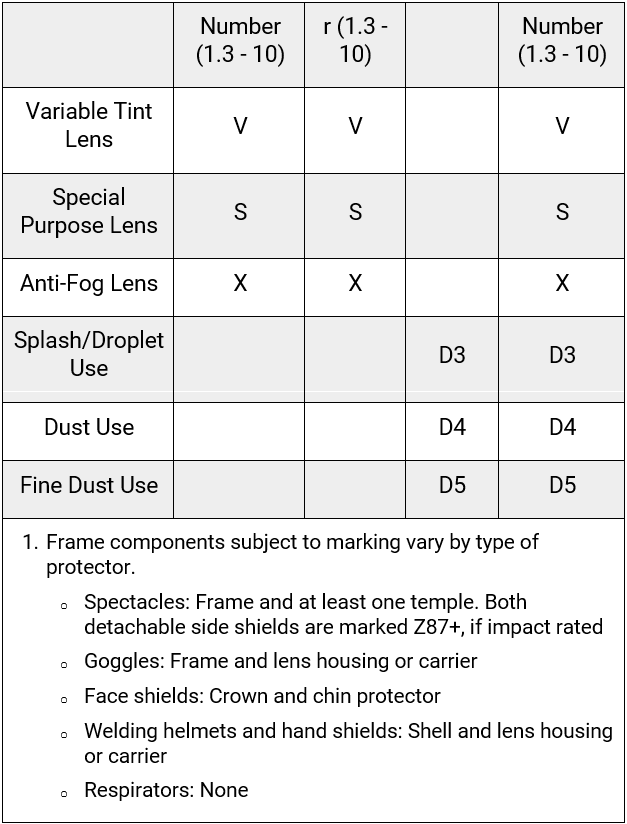

ANSI/ISEA Z87.1-2020 Markings

All compliant protections must be permanently and legibly marked as shown in the following table. Markings for lens type and use applications are only required when claims for such protection are made by the manufacturer.

These markings must be placed in proximity to each other in this sequence:

- Manufacturer’s marks/logos (exempt from proximity requirement if they are clearly present elsewhere)

- Standard designation

- Coverage

- Optical level

- Optional hazard-specific marks (if applicable)

- Impact-protector marking

- Optical radiation marking

- Droplet and splash marking

- Dust marking

- Fine dust marking

- Optional Design marks (if applicable)

- Anti-fog treatment

Commonly Asked Questions

Q: How long must lenses marked as anti-fog remain free from fogging?

A: According to the ANSI/ISEA Z87.1-2020 lenses marked as having anti-fog properties must remain free from fogging for a minimum of eight seconds. This testing applies to the lenses only and does not assess the resistance to fogging of the complete device.

Q: What should the lenses of my protective eyewear be made of?

A: Most lenses are made from polycarbonate. This lightweight plastic absorbs 99% of UV light, can be purchased in welding shades and is highly impact resistant.

Q: I need safety glasses for work, but I already wear prescription eyewear. What are my options?

A: Workers who wear prescription lenses must wear a pair of safety glasses that incorporate the prescription in its design, wear safety glasses that can be worn over prescription lenses without disturbing the proper position of either, or wear a pair of reader eyewear that would meet the user’s refractive need. Eyewear frames and prescription insert holders are available through Grainger for your convenience.

Related Articles

Quick Tips #192: Hazard Assessment Form

Sources

29 CFR 1910.132, General Requirements

29 CFR 1910.133, Eye and Face Protection

ANSI/ISEAZ87.1-2020, American National Standard for Occupational and Educational Eye and Face Protection Devices

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how